When it comes to textiles, durability is key. Fabrics, whether used in clothing, upholstery, or industrial applications, need to withstand the wear and tear of daily life. Tensile and tear resistance tests play a pivotal role in determining the quality and longevity of fabrics. In this comprehensive guide, we will delve into the world of fabric testing, exploring the importance of tensile and tear resistance tests, the methods employed, and how these tests impact the industry.

Understanding the Basics

What Are Tensile and Tear Resistance Tests?

Tensile and tear resistance tests are standardized procedures designed to evaluate a fabric’s ability to withstand stretching and tearing forces. These tests are essential for various industries, such as fashion, automotive, and manufacturing, where fabric strength and durability are of utmost importance.

Why Are These Tests Important?

Tensile and tear resistance tests provide critical insights into a fabric’s performance and longevity. By subjecting fabrics to controlled stress, manufacturers can determine their suitability for specific applications. Knowing a fabric’s tensile and tear resistance is vital for ensuring customer satisfaction and reducing costly product failures.

Conducting Tensile Resistance Tests

Test Apparatus and Setup

To perform a tensile resistance test, a fabric sample is clamped at both ends and subjected to a gradually increasing force. The objective is to measure the fabric’s resistance to elongation. The test apparatus typically consists of a testing machine equipped with clamps, and specialized grips for different fabric types.

Calculating Key Parameters

During the test, parameters such as the force applied, elongation, and stress are recorded. These parameters help determine the fabric’s breaking point, elongation at break, and stress at break. These values are crucial for evaluating a fabric’s strength and flexibility.

Standards and Compliance

Tensile resistance tests are conducted following specific standards, such as ASTM D5034 and ISO 13934-1. Adhering to these standards ensures consistency and accuracy in the results, allowing for meaningful comparisons between different fabric samples.

The Significance of Tear Resistance Tests

Test Methodology

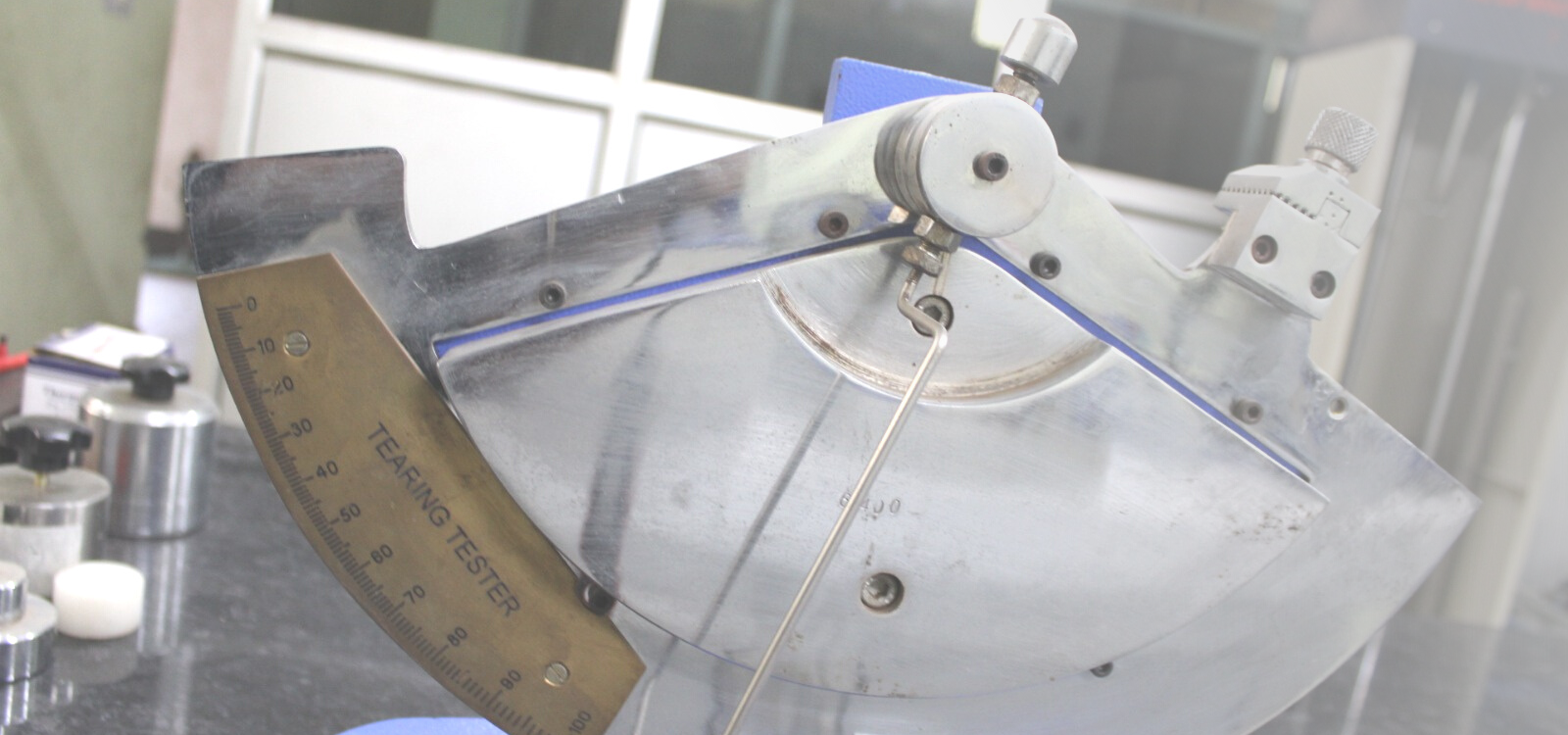

Tear resistance tests focus on a fabric’s resistance to tearing. The fabric sample is typically incised, and the force required to propagate the tear is measured. This test helps determine a fabric’s ability to withstand forces that might lead to accidental damage.

Interpreting Results

The results of tear resistance tests are vital for various applications, from designing durable outdoor gear to ensuring the safety of airbags in the automotive industry. A higher tear resistance indicates a fabric’s ability to resist punctures, making it ideal for rugged applications.

Common Standards

Tear resistance tests follow standards like ASTM D2261 and ISO 13937-2, providing a universally accepted benchmark for evaluating fabric performance.

The Intersection of Tensile and Tear Resistance

Real-World Applications

The combination of tensile and tear resistance data offers a holistic view of a fabric’s performance. For instance, in the fashion industry, a fabric with high tensile strength and tear resistance is ideal for clothing that needs to withstand daily wear and tear.

Innovations in Fabric Technology

Manufacturers are continually innovating to develop fabrics with superior tensile and tear resistance. This is particularly evident in industries like sports equipment, where lightweight yet durable materials are essential for peak performance.

Challenges in Testing

While standardized tests provide valuable insights, real-world conditions can be more complex. Factors like environmental stress, UV exposure, and chemical exposure can affect a fabric’s performance over time, necessitating ongoing quality control.

Conclusion

In the world of textiles, the durability and quality of fabrics are non-negotiable. Tensile and tear resistance tests are indispensable tools for manufacturers and designers, ensuring that fabrics meet the demands of various applications. By understanding these tests and their significance, you can make informed choices when it comes to selecting fabrics for your specific needs.